2022-03-11

-

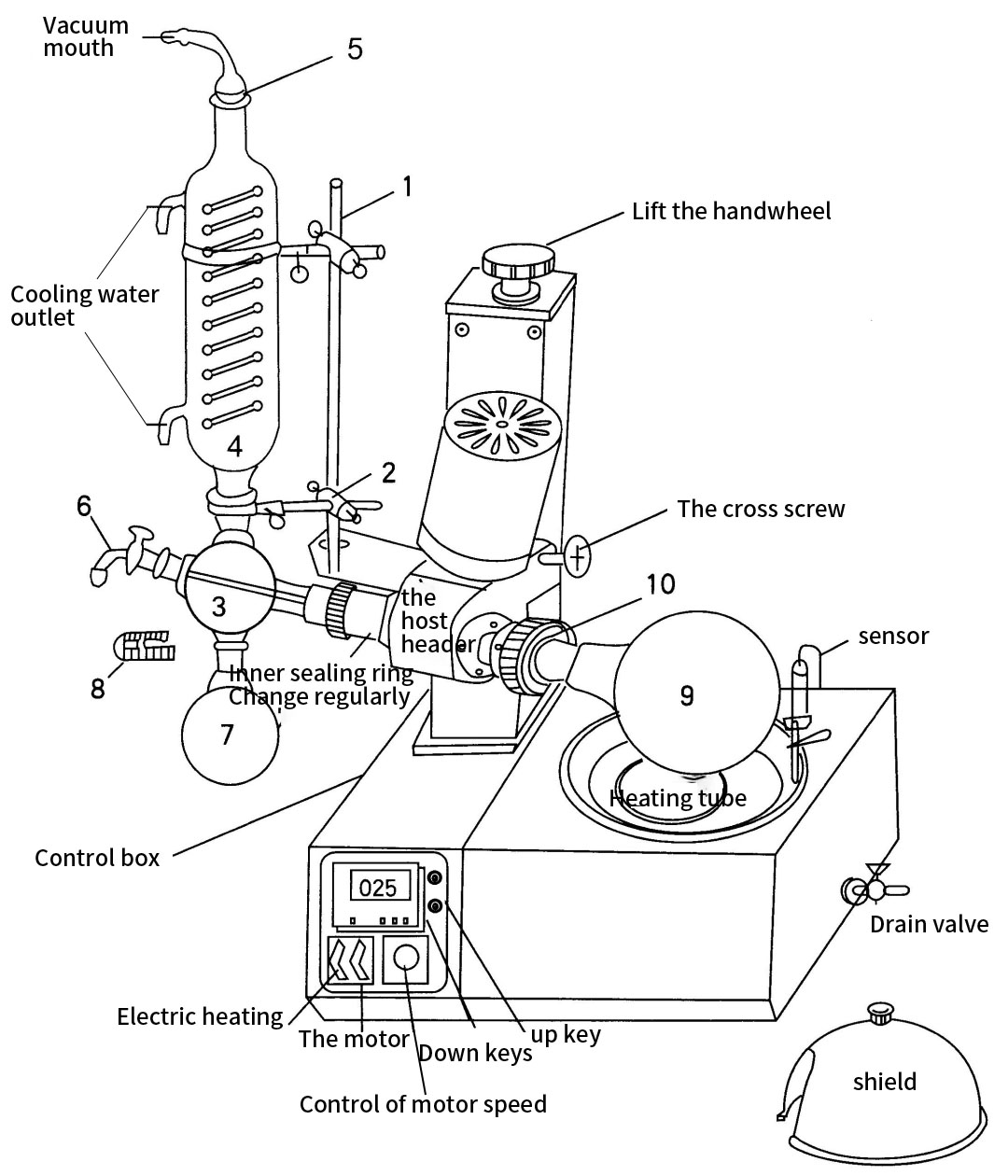

Rotary evaporator, also known as rotary evaporator, is a commonly used laboratory equipment. It consists of a motor, a distillation bottle, a heating pot, a condenser tube and other parts. It is mainly used for continuous distillation of volatile solvents under reduced pressure conditions. It is used in chemistry, chemical industry , biomedicine and other fields.

The basic principle of rotary evaporator

The basic principle is vacuum distillation, that is, under reduced pressure, the rotary evaporation flask (flask) is placed in a water bath and heated while rotating, which can increase the evaporation area and facilitate the diffusion and evaporation of the solution in the bottle.

The structure of the rotary evaporator

Precautions for the use of rotary evaporator

If the rotary evaporator is used improperly, it is easy to cause damage to the equipment, so some precautions should be paid attention to during use, as follows:

1. The glass parts should be handled with care, and should be washed, dried or dried before installation.

2. Each grinding port, sealing surface sealing ring and joint need to be coated with a layer of vacuum grease before installation.

3. Water must be added before the heating tank is energized, and dry burning without water is not allowed.

4. If the vacuum cannot be pumped up, it needs to be checked:

(1) Whether the joints and interfaces are sealed

(2) Whether the sealing ring and the sealing surface are effective

(3) Whether the vacuum grease between the main shaft and the sealing ring is well coated

(4) Whether the vacuum pump and its hose are leaking

(5) Whether the glass pieces are cracked, broken or damaged

5. About vacuum degree

The vacuum degree is the most important process parameter of the rotary evaporator, and users often encounter the problem that the vacuum degree cannot be increased. It is usually related to the nature of the solvent used. Solvents such as water, ethanol, acetic acid, petroleum ether, and chloroform are commonly used in the detection. However, general vacuum pumps cannot resist strong organic solvents. Special vacuum pumps with strong corrosion resistance can be selected, and water circulation vacuum pumps are recommended.

How to check whether the instrument is leaking:

Pinch off the external vacuum hose, and observe whether the vacuum gauge on the instrument can keep air-tight for five minutes. If there is air leakage, check whether the sealing ring on each sealing joint and rotating shaft is effective. On the contrary, if the instrument is normal, it is necessary to check the vacuum pump and vacuum pipeline.

6. About the temperature rise of the motor

If a certain type of motor adopts three-phase, 220V special motor, E-class insulation, the winding adopts polyester high-strength enameled wire, the surface temperature rise of the motor is used continuously when the altitude does not exceed 1000 meters and the ambient temperature does not exceed 40 °C (the surface temperature of the motor and the environment It is normal for the temperature difference) not to exceed 45 °C. If the temperature rise exceeds 45 °C, check the relevant transmission lubrication system.

Rotary evaporator maintenance

1. Glass parts: when there is serious dirt, it can be cleaned with dilute hydrochloric acid.

2. PTFE interface: Generally, it does not need to be disassembled and washed. If there is serious dirt, it can be disassembled and washed. The water in the water bath should be replaced and cleaned.

3. Seals: Always check the degree of wear (corrosion) of the seals, and replace the worn seals in time to ensure the vacuum degree of the instrument.

Tips for Buying a Rotary Evaporator

Before purchasing a rotary evaporator, it is necessary to clarify some questions, such as the amount of distillation at one time, the approximate number of samples that need to be distilled per day, what solvents are expected to be distilled, what is the approximate range of the boiling points of the solvents, and whether these solvents are Flammable, explosive or toxic and harmful solvents. After determining the experimental requirements and the type of solvent to be distilled, you can start purchasing a rotary evaporator.

1. Clarify the specifications of the rotary evaporator

The specifications of the rotary evaporator are usually distinguished by the volume of the evaporating flask. The size of the evaporating flask required depends on the quantity of the material to be evaporated. Generally speaking, 2L, 3L and 5L rotary evaporators are suitable for small laboratory experiments; 5L, 10L and 20L are suitable for pilot test; 20L and 50L are suitable for pilot test and production. Of course, under special circumstances, the volume of the evaporating flask can also be expanded by means of the continuous feeding pipe, thereby expanding the volume of one continuous distillation to a certain extent.

2. Clarify the distillation tasks that the rotary evaporator needs to complete

2.1. Distillation efficiency

The distillation efficiency of the rotary evaporator determines the number of samples that can be distilled per day. In the case of the same solvent, the higher the distillation efficiency, the greater the number of samples to be distilled. If the sample volume is large, you need to pay more attention to the distillation efficiency when purchasing a rotary evaporator.

2.2. Security risk assessment

The safety risk of distillation mainly comes from the solvent and heating medium of distillation.

1) If the heating medium is silicone oil, the ignition point should be at least 25°C higher than the maximum temperature of the heating pot.

2) If the distillation solvent is flammable and explosive, explosion-proof glass components can be used as the first choice. It is best if the instrument can automatically deflate after the distillation is completed, so as to avoid manual deflation too fast and cause an explosion.

3) To optimize the laboratory environment, a secondary condensation device can be selected to maximize the recovery of the distillation solvent.