PRODUCTS CENTER

-

Product name:24L autoclave -

Order number: -

Model: -

Stock status:Delivery according to contract -

Logistics:by sea, by air, by express, etc.

- Product Introduction

- Details Page

-

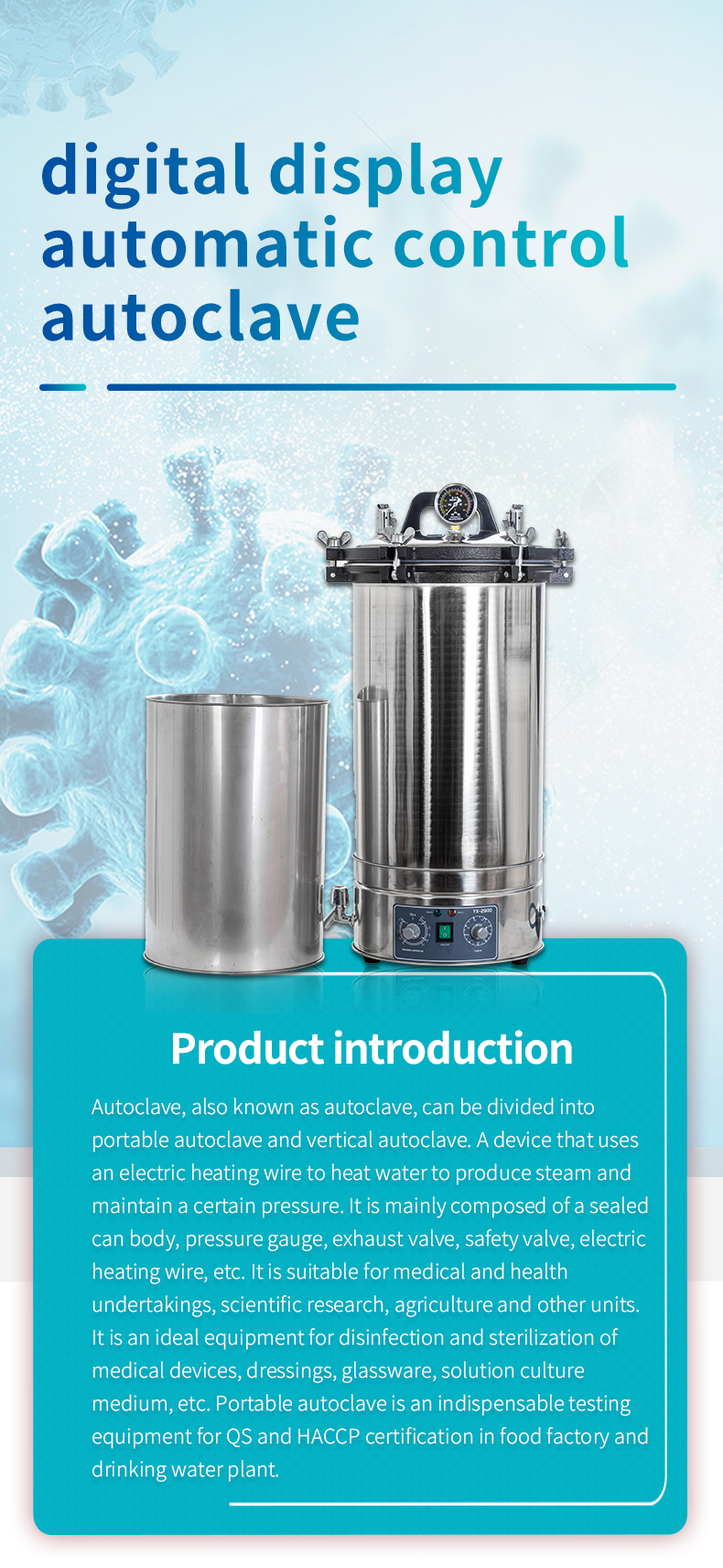

1. Product introduction

The 24L high-pressure sterilizer adopts electric heating water, which produces saturated steam under airtight conditions, which quickly moistens, heats and penetrates the sterilized object, and maintains pressure and heat preservation for a period of time. to be killed to achieve the purpose of sterilization. The sterilizer is portable, beautiful in appearance, easy to use, reliable in sterilization effect and good in safety performance. This product is suitable for small medical institutions, laboratories, etc. to kill a small amount of surgical instruments, dressings, glassware, culture medium, etc.

In a closed steamer, the steam in it cannot escape, and the pressure continues to rise, so that the boiling point of the water continues to increase, thereby increasing the temperature in the pot. Under the pressure of 0.1MPa, the temperature in the pot reaches 121℃. At this steam temperature, its highly heat-resistant spores can be quickly killed.

Note: Completely remove the air in the pot, so that the pot is full of water vapor, and sterilization can be clean. There are several different methods of high pressure sterilization and air release, but the purpose is to exhaust the air, so that the temperature in the pot is evenly heated to ensure clean sterilization. The common method is: close the air release valve, after the power is turned on, when the pressure rises to 0.05MPa, open the air release valve to release the air, and close the air release valve after the pointer of the pressure gauge returns to zero. After closing the valve and then energizing, when the pressure gauge rises to 0.1MPa, start timing and maintain the pressure at 0.1-0.15MPa for 20 minutes.

After the pressure holding time is reached, the power supply can be cut off. When the pressure drops to 0.5MPa, the steam can be released slowly. Care should be taken not to reduce the pressure too fast, which will cause intense decompression boiling and overflow the liquid in the container. When the pressure drops to zero, the lid can be opened, the medium is taken out, and placed on the platform to wait for condensation. Do not deflate for a long time, causing changes in the composition of the medium, so that the medium cannot be tilted. Once placed for too long, the lid cannot be opened due to the negative pressure in the boiler. As long as the air release valve is opened, the atmospheric pressure is entered, and the internal and external pressures are balanced, and the lid can be easily opened.

For items that do not deteriorate after autoclaving, such as sterile water, cultivation medium, and inoculation utensils, the sterilization time can be extended or the pressure can be increased. The medium must strictly abide by the pressure holding time, not only to maintain the pressure effect, but also to prevent the components in the medium from deteriorating or reducing the effectiveness, and the time cannot be arbitrarily extended.

Steps

1. First take out the inner sterilization bucket, and then add an appropriate amount of water to the outer pot to make the water surface level with the triangular shelf.

2. Put it back into the sterilization barrel and load the items to be sterilized. Be careful not to pack too much, so as not to hinder the flow of steam and affect the sterilization effect. The conical flask and the mouth end of the test tube should not be in contact with the barrel wall, so as to prevent the condensed water from drenching the paper at the mouth and penetrating into the cotton plug.

3. Put the cap on, and insert the capped exhaust hose into the exhaust slot of the inner sterilization barrel. Tighten the opposite two bolts at the same time in a symmetrical manner, so that the bolts are tight and consistent, and do not leak air.

4. Heat with electric stove or gas, and open the exhaust valve at the same time to make the water boil to remove the cold air in the pot. After the cold air is completely exhausted, close the exhaust valve and let the temperature in the pot gradually rise as the steam pressure increases. When the pressure in the pot rises to the required pressure, control the heat source and maintain the pressure for the required time. This experiment uses 1.05kg/cm2, 121.3 ℃, 20 minutes sterilization.

5. When the time required for sterilization is up, cut off the power supply or turn off the gas, and let the temperature in the sterilization pot drop naturally. When the pressure of the pressure gauge drops to 0, open the exhaust valve, loosen the bolt, open the cover, and take out the sterilizer. thing. If the pressure does not drop to 0, open the exhaust valve, the pressure in the pot will drop suddenly, and the medium in the container will be flushed out of the mouth of the flask or the test tube due to the unbalanced internal and external pressure, causing the cotton plug to contaminate the medium. Pollution.

6. Put the removed sterilized medium into a 37°C incubator for 24 hours. After inspection, if there is no growth of bacteria, it can be used.

2. Product parameters

1. Applicable power supply: ~220V±10% 50Hz±1Hz

2. Consumption function: 8L: 1.2kVA, 18L, 24L: 2KVA

3. Working temperature: 126-1+2℃

4. Normal use conditions Environment: Ambient temperature: 5~ 40℃, relative humidity: ≤80%

5. Atmospheric pressure: 70kPa-106kPa

3. Product Features

1. The main body of the container of this product is made of 0Gr18Ni9Ti stainless steel material, which is not only resistant to acid and alkali, but also safe and has a long service life, which is 3-5 times longer than that of aluminum alloy products.

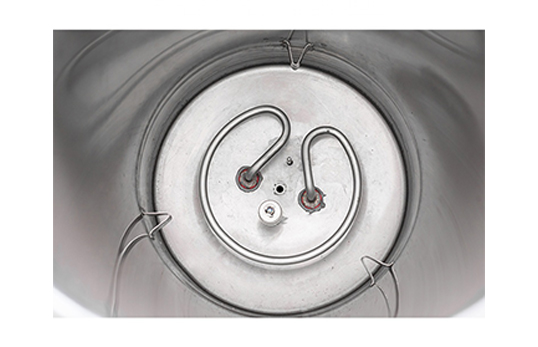

2. The product is heated by immersion electric heating tube, which consumes less power and heats up quickly.

3. A variety of heating methods can be used, such as: liquefied gas, coal gas, coal stove, firewood, etc.

4. When the steam pressure exceeds 0.165MPa, the safety valve can automatically release the excessive pressure to ensure safety.

-