PRODUCTS CENTER

-

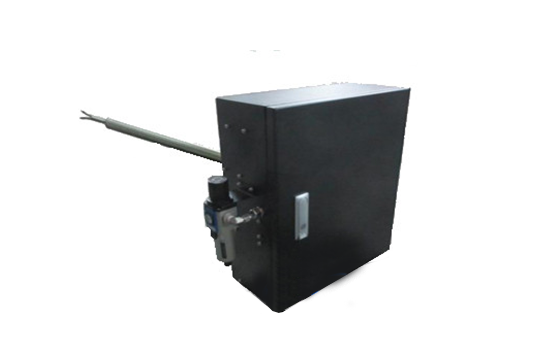

Product name:JCY-PT100 type temperature pressure flow integrated monitor -

Order number: -

Model:JCY-PT100 -

Stock status: -

Logistics:

- Product Introduction

-

1. Product introduction

product description:

JCY-PT100 temperature-pressure-flow integrated detector has high-precision differential pressure /static pressure sensor and is equipped with a backflushing unit. It is an integrated temperature detector specially developed for high dust, high temperature and high humidity environments for continuous detection of flue gas emissions. , Pressure, flow velocity detector, in line with the requirements of relevant national standards, can be used for flue gas emission detection system (CEMS) for real-time continuous measurement of flue gas temperature, pressure, velocity and flow. The measurement principle is: the primary pressure taking element adopts the traditional pitot tube measurement method. After correct installation, the full pressure and back pressure pressure taking pipes of the pitot tube transmit the detected dynamic pressure and static pressure to the differential pressure transmitter respectively. , The differential pressure transmitter converts the difference between the dynamic pressure and the static pressure into a 4-20mA square root proportional current and transmits it to the data acquisition module of the distribution box, and the computer in the CEMS cabinet performs data processing.

product composition:

The structure of the integrated temperature-pressure-flow measuring device mainly includes differential pressure transmitter, static pressure sensor, thermal resistance (or thermocouple), pitot tube, backflushing solenoid valve, temperature and pressure compensation, etc.

Installation instructions:

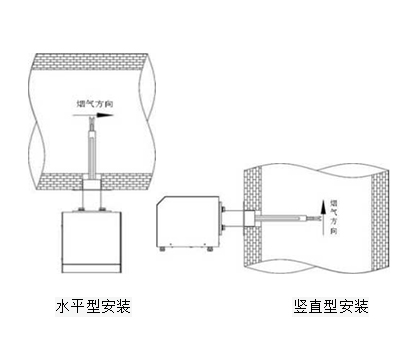

JCY-PT100 differential pressure transmitter needs to measure two pressures, total pressure and static pressure when measuring differential pressure. Therefore, when installing the pitot tube, pay attention to the direction of the pitot tube, and ensure that two pressures are taken during installation. The port should be consistent with the flow direction of the flue gas, that is, the full pressure measurement end needs to be aligned with the direction where the flue gas comes, and the static pressure measurement end should be aligned with the direction where the flue gas leaves.

Installation is divided into vertical installation and horizontal installation, as shown in the figure:

2. Product parameters

1. Measurement range: 0~40 m/s; 0~15.5 m/s (optional)

2. Measurement accuracy ±5%FS

3. Calibration frequency: 12 months

4. Response time: <1s

5. Output signal : 4~20mA square root proportional current

6. Overvoltage limit of differential pressure transmitter: 1.0MPa

7. Pitot tube material: 316, 316L stainless steel

8. Power supply: 220VAC, 50Hz

9. Pitot tube insertion length: 500~1700mm ( Optional)

10. Pressure transmitter range: -5~5kPa (customizable)

11. Temperature transmitter range: 0~300℃ (customizable)

12. Medium temperature range: -40°C~500°C

13. Environment Temperature range: -40℃~85℃

14. Storage temperature: 0~50℃

15. Storage humidity: 0~85%RH3. Product Features

JCY-PT100The inner and outer surfaces of the pitot tube are specially treated, which can effectively avoid flue gas corrosion and reduce dust adhesion. The backflushing solenoid valve is mainly used for the system backflushing during the measurement of dirty gas (such as the flue gas discharged from the boiler): when the detection hole of the probe adheres and accumulates dust and dirt, the solenoid valve is opened regularly or according to a predetermined program, and the compressed air is turned on. At the same time, connect two pressure pipes for blowing off. During normal measurement, the solenoid valve is in a closed state . In addition, the instrument also has the following characteristics:

1. Real-time measurement of temperature, pressure and flow rate of flue gas, and output through 3 channels of 4~20mA analog signals

2. It can adapt to extreme conditions such as high dust, high temperature and high humidity

3. High measurement accuracy, good reliability, and long-term continuous Work

4. Equipped with an automatic backflushing unit, which can regularly clean the particles in the dynamic pressure and static pressure ends of the pitot tube.

5. The structure is compact, the installation and wiring are convenient, and the maintenance is low.